Mesoscopic studies of the role of defects in structural phase transformations

A mesoscopic description (nano to micrometer) of physical processes in solids, where atomic length scales merge with those of the continuum, represents a crucial and perhaps most challenging aspect of understanding material behavior. This arises, for example, during displacive (martensitic) phase transformations where the distortions associated with the strains in unit cells and intra-unit cell displacements (or shuffles) propagate over larger distances so that competing long-range effects lead to the formation of inhomogeneities such as interfaces, spatially correlated domains and complex microstructure.

Our objective in this research is to incorporate dislocations into the Landau theory to study martensitic phase transformations affected by plastic deformation. We consider an anisotropic medium that is described by the elastic constants corresponding to the high-temperature cubic phase. Utilizing Kröner's continuum theory of dislocations, we develop a self-consistent scheme that allows simultaneous calculation of the microstructure and the evolution of the dislocation density. Above is a result of the simulation of a material whose high-temperature phase is square (or cubic) and the low-temperature phase is rectangular (or tetragonal). Below Tc, the microstructure is characterized by alternating regions of the two variants of the martensite. The minimum of the free energy corresponds to the alternating dislocation walls that decorate the twin boundaries. At present, we are working on a fully 3D theory that will allow for studies of the interplay between microstructure and long-range elastic fields of dislocations, in particular investigations of dislocation pattern formation.

Collaboration: R. Gröger (IPM), T. Lookman (LANL), A. Saxena (LANL)

Complex plastic deformation of bcc metals

The plastic deformation of crystalline materials is governed by motion of dislocations. In close-packed metals such as face-centered cubic (fcc) and hexagonal close-packed (hcp) metals that deform by basal slip, the dislocations possess planar cores and so their slip planes are well defined. This allows for formulating relatively simple macroscopic yield criteria the most common of which are those due to von Mises, Tresca, Mohr and Coulomb, or Drucker and Prager. On the other hand, plastic deformation of body-centered cubic (bcc) metals is governed mainly by the motion of 1/2<111> screw dislocations that possess non-planar cores and thus their slip planes are not well defined. The same applies to the {0110} prism slip and even more so to the {0111} pyramidal slip in hcp metals. Moreover, owing to the non-planar character of the core the dislocation glide may be affected by all components of the applied stress tensor and, therefore, the core symmetry is generally broken under the operation of external stresses. Consequently, both the yield and flow rules for bcc metals are significantly more complex and can be formulated only after one gains a complete knowledge of the behavior of screw dislocations on the atomic scale.

|

|

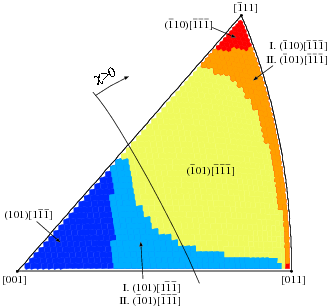

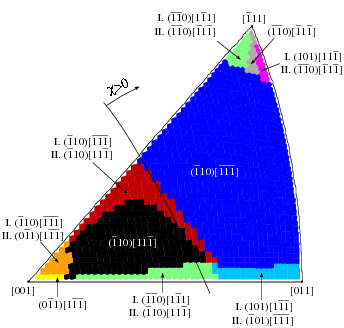

In order to elucidate the origin of the plastic deformation of bcc metals, we performed an extensive computational study of the behavior of 1/2<111> screw dislocations under stress utilizing the state-of-the-art Bond Order Potentials (BOP) for these materials. These calculations provide the dependence of the critical resolved shear stress (Peierls stress) to move the dislocation on the orientation of the plane in which it is applied and on the shear stress perpendicular to the slip direction. These results are subsequently used to obtain yield criteria that capture the complex behavior of these dislocations in bcc metals. Under tension, the most operative slip system is the most highly stressed (-101)[111] system. However, under compression the activity of individual slip system varies with orientation. This is demonstrated in the figures above that show the regions of activity of the primary slip system(s) in molybdenum and tungsten. In the case of molybdenum, the obtained map agrees well with many experimental observations performed in the past fifty years. However, similar comparison for tungsten cannot be made due to insufficient experimental data. In this case, computer simulations serve as an indispensable source of insight into the plastic deformation of this technologically important metal.

Collaboration: R. Gröger (IPM), V. Vitek (UPenn)